Technology and R&D

We use innovative and modern technologies for the cleaning of ventilation and HVAC systems. We develop and improve our own equipment and application technologies in order to constantly offer a better service and efficiency to our customers. The cleaning is done with different technologies, from rotation brushes to dry ice blasting to chemical solutions.

Categories:

„Thanks to our technology we can provide cleaning without production breaks!”

Most of our equipment comes from our in-house R&D department. Our engineers design and construct new machines and also constantly improve the current equipment assortment to fit the needs of our customers.

Dry Ice Blasting

Dry ice blasting is an effective and environmentally friendly method of removing deposits and contaminants. It is usable on the spot, it is non-abrasive and it does not create any secondary waste.

Dry ice is the solid form of the pure carbon dioxide – CO2.

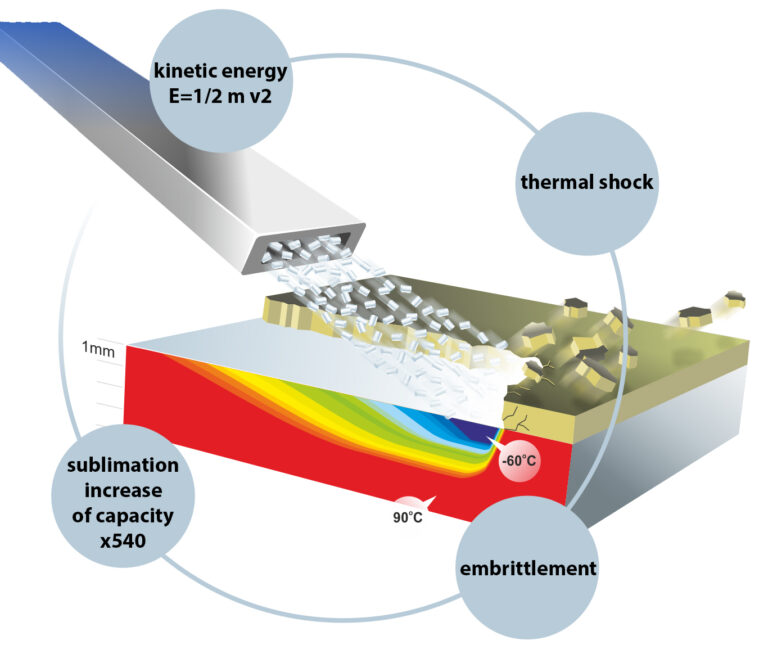

Dry ice blasting technology uses the unique qualities of this material:

KINETIC ENERGY

Solid particles of CO2 are accelerated to supersonic speed in the nozzle and thereby provides high kinetic energy.

THERMAL SHOCK

Dry ice has a temperature of – 78.5°C. Therefore it undercools the surface and the contaminant embrittles thanks to the temperature difference.

REVERSE FRACTURING

As the dry ice hits the surface, it expands rapidly and this shock wave tears off corrupted contaminants.

NON-ABRASIVE

The low hardness of dry ice (no. 2 on Mohs scale of hardness) protects the surface against damage or scratches.

NON-REACTIVE GAS

CO2 is an inert, non-toxic, electrically non-conductive gas and has no negative effect on any material.

Talpa Brushes

This unique system, developed by Alkion, uses hydraulicly powered rotation brushes made of different hard materials. It reaches up to 1000 revolutions per minute. It is a very effective system for the cleaning of difficult and hard deposits in certain industries. We combine this system with a powerful blower exhaust.

Seta Brushes

We use special rotation brushes, manufactured by Alkion. The brush can be powered electrically or pneumatically. Different sizes, shapes and materials of the brushes allow effective cleaning of ducts from 100 mm up to 1000 mm in diameter. In combination with environmentally-friendly chemical solutions or water, it is a very powerful method for the cleaning and following disinfection of exhaust systems.

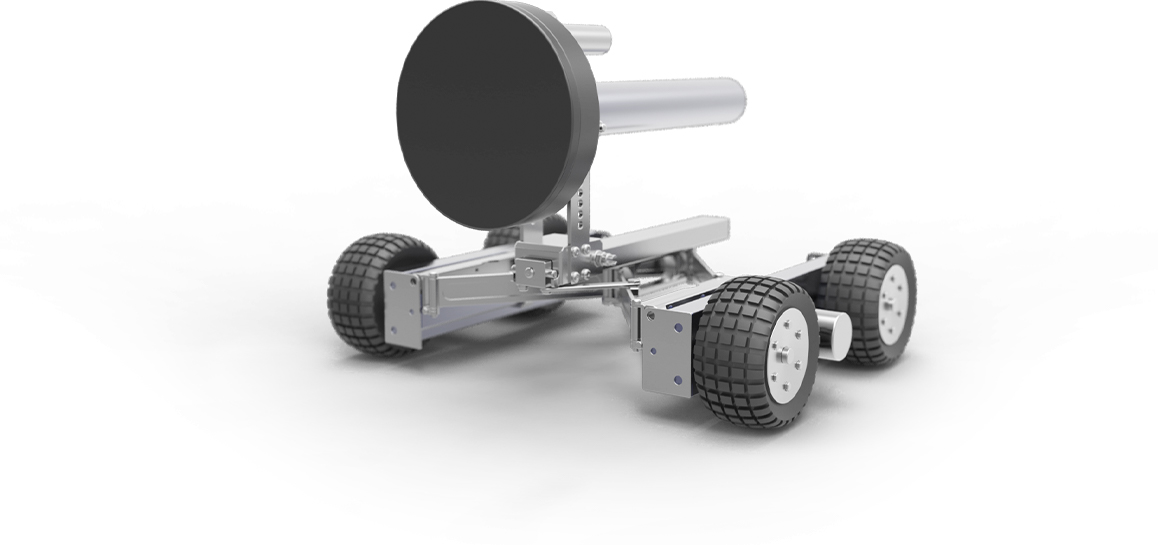

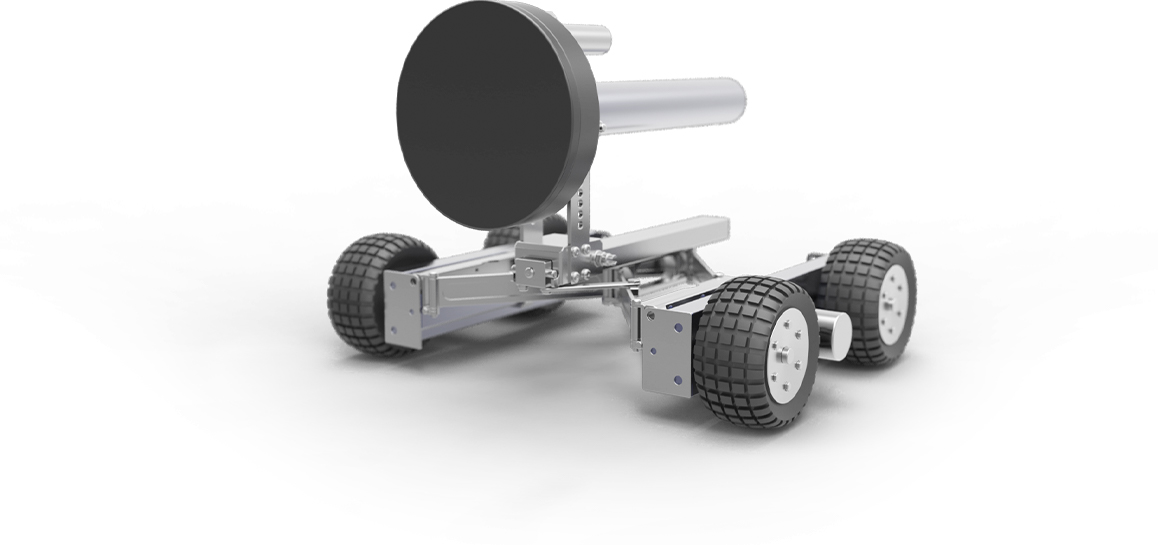

Robot C-REX

This robotic device was developed for the cleaning of industrial exhausts and HVAC systems, using dry ice blasting technology. Thanks to its unique construction, it is able to go through and clean curves up to 70°, ducts with branches and different diameters and shapes, from 250 up to 800 mm. The speed of the robot and its circulating various nozzles can be regulated in different ways using a remote control in order to determine the most efficient process for each cleaning application. Equipped with LED lights, a permanent control of the progess and cleaning quality is given.

Ventilator and Blower

Blower Exhaust

We use the blower for the suction of heavy industrial contaminants from the ducts. The blower operates on a different principle compared to standard industrial ventilators or vacuum cleaners. The blower can create a powerful negative pressure up to -0,8MPa and maintains its suction power even at higher loads. Hence, we can suck out bigger pieces of dirt, heavy greasy dust or sand. Contaminants are collected in a cyclone and in the filters behind the cyclone.

It is often necessary to fully replace the existing on-site exhaust system with our own high-pressure ventilator in order to manage collecting heavy debris and contaminants. Its performance reaches up to 90 m3 / min. The air which is exhausted by the ventilator is further filtered through a cyclone and filters, representing 16 m².

Contact Us

You need cleaning, a quote, consultation or have questions? Please complete the form below and we will get back to you within 24 hours!