AEROSEAL

When was the last time you assessed the effectiveness of your ductwork system sealing? There‘s a high probability that since then, leaks may have occurred, resulting in higher energy consumption and costing you money. With AEROSEAL, we can rectify this issue.

Why should you consider sealing, and how can AEROSEAL help you?

Electric energy savings

Electric energy savings up to tens of percents

Air tightness class D

Guaranteed air tightness class D according to norms

ROI in 3 to 5 years

Significant increase of effectiveness and efficiency of a ductwork system

No need for dismantling the ductwork

Sealing of leaks up to 1,5 cm in diameter without dismantling the ductwork

Efficient Modernization of your HVAC System

Leakages often occur during the installation and use of ductwork systems, significantly impacting the performance of the entire HVAC system and leading to increased operational requirements and energy costs. Whether you‘re involved in reconstruction or modernization of your current HVAC system, AEROSEAL offers a rapid and effective solution for sealing ductwork systems. Additionally, it ensures the attainment of the highest possible air-tightness class.

Construction of a New Ductwork system

AEROSEAL can be employed during the installation of a new ductwork system, ensuring adherence to the strictest air-tightness standards right from the outset of operation. Unlikeconventional sealing methods, AEROSEAL addresses air leakage with precision machinery.

A Positive Impact: ESG and EPC

AEROSEAL effectively seals ductwork systems, reducing energy losses and improving air quality and employee comfort. In the context of Energy Performance Contracting (EPC), AEROSEAL assists corporations in achieving energy efficiency, reducing greenhouse gas emissions, and meeting energy savings standards. This makes the technology a significant preventive measure for sustainable energy usage, which clients can include in their ESG (Environmental, Social, and Governance) reporting.

ESG

ESG (Environmental, Social, Governance) is a framework that assists companies in developing, measuring, and enhancing their sustainable business strategies and practices. A high ESG score not only facilitates access to favorable loans but also serves as a crucial criterion for investors.

EPC

EPC (Energy Performance Certificate) is an integral component of energy assessments. It evaluates energy management strategies, including proposed construction measures, their costs, and their potential impact. In certain jurisdictions, EPC is a legal requirement for certain types of buildings.

How Does AEROSEAL Work?

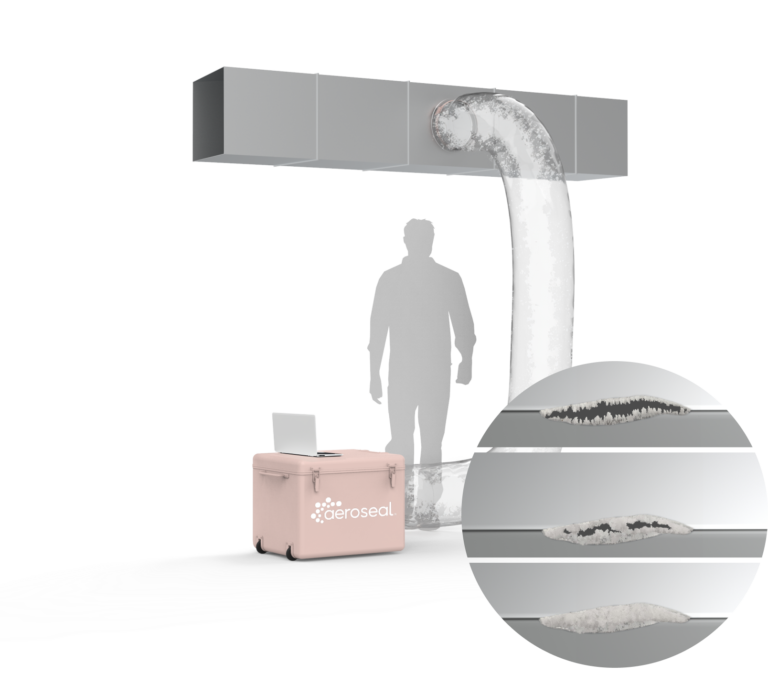

AEROSEAL technology is built upon a mist-like liquid substance, known as aerosol, which is dispersed into the ductwork system to reach all its components. As it flows through the system, it seeks out areas of decreased pressure, where air leakages occur. Tiny particles of AEROSEAL then fill these gaps until they are completely sealed. Subsequently, AEROSEAL hardens, effectively resolving the issue.

What Makes AEROSEAL‘s Solution Unique?

- It can seal gaps with diameters up to 1.5 cm

- The application itself does not subject the ductwork

system to excessive stress - Once hardened, it can withstand pressures

of up to 2000 Pa. - There is no requirement for physical access

to the entire ductwork distribution system

Learn the principle of AEROSEAL technology in one minute

At first glance, this technology may seem very complicated. That’s why we’ve prepared a short animation to show you how AEROSEAL works and what exactly happens in the ductwork system.

How the sealing process itself works

Cleaning

Before applying AEROSEAL technology, we ensure that the ductwork is properly cleaned and disinfected. We offer customized turnkey solutions tailored to your needs. In many cases, we can provide cleaning services without disrupting

your production.

Measurement

Prior to the implementation, we conduct air-tightness measurements of the ductwork system using air-leakage tests across various air-tightness classes. Following the application of AEROSEAL, we perform another round of measurements.

Sealing

Utilizing AEROSEAL technology, we comprehensively seal all identified air-leakage spots and gaps, initially identified through decreased air pressure in specific areas.

Why Choose Alkion?

Safety

We adhere to stringent safety protocols, utilizing only verified and approved technologies, including chemical instruments.

Experience

We have extensive experience in duct cleaning, serving prestigious clients such as the Four Seasons Hotel in Prague and AIDA ocean liners.

Professionalism

We hold a range of internationally recognized certifications, including VDI 6022B, NADCA, and EVHA.